If you ask Hollywood, the world teeming with robots and artificial intelligence is a no-brainer. Movies like “The Terminator,” “WALL-E” and “Blade Runner” have all cast intelligent automata as the wings upon which the future — mostly dystopian — swoops in. In fact, some very big names in science and engineering have recently joined voices in cautioning against unchecked intelligence development. Tesla’s Elon Musk and theoretical physicist Stephen Hawking have both predicted catastrophe should we make dumb choices when building smart machines.

Of those sounding a much less ominous tone are many of the people actually working on the cutting edge of robotics. While progress needs to be carefully considered, they say, prognostications of malevolence overlook the very real benefits the machines have already started to produce. No matter what you believe on this subject, there’s no doubt that smart machines are firmly planted in the global zeitgeist these days.

“You’ve got people painting a very dark picture of robotics,” says John Lizzi, who heads GE’s research lab on distributed intelligent systems. “The concept of AI taking over is interesting, but getting anywhere near that type of capability is very far away. And while the rest of the world is dreaming up these science-fiction futures, we’re taking the technology and solving real problems today.”

Since the first robots started working on factory floors 55 years ago, a significant number of smart machines have come on the market and are now under development. In recent years, several have grabbed attention for how they promise to improve work and home life. These include Google’s self-driving cars as well as humble domestic helpers like iRobot’s Roomba. The still-unwritten future of the robots rising from the DARPA Robotics Challenge could one day potentially save lives after disasters.

Then, of course, there are the millions of robotic arms and other industrial machines deployed in automotive manufacturing, healthcare and other industries. They have proven themselves thoroughly in factories and their expanding skills mean that the ranks of bots toiling among us is certain to grow. According to the International Federation of Robotics (IFR), 1.5 million industrial robots were operating at the end of 2014, and an estimated 12 percent yearly increase in that number means 2.3 million will be operating by the end of 2018. The vast majority of those are the precise but limited robotic arms that have become commonplace on automotive production lines.

But for the robotics revolution to come, as the IFR and industry insiders forecast, the machines will need to get smarter. In fact, experts in the field say that revolution is coming thanks to robots getting the brains to become collaborative — to perceive and respond to their environment, and to safely work side by side with their human colleagues.

For this idea to come to fruition — Rethink Robotic’s Baxter and Sawyer robotshave already made important first steps — the machines will need to perform on their own, learn how to do new tasks by watching people and know when to ask for help. That’s going to require imbuing robots with artificial intelligence powerful enough to give them perception, reasoning and cognition. Just how much of these qualities they’ll need is still a hotly debated matter.

The most recent discussion is taking place this week at the 2015 Robotics Leadership Summit, sponsored by GE and held at the company’s Global Research Center in Niskayuna, New York Among those speaking are Rodney Brooks, the founder, chairman and CTO of Rethink Robotics; Chia-Peng Day, Foxconn’s robotics chief; and Red Whittaker, a prominent Carnegie Mellon University researcher who has been instrumental in putting robots to work in space, mines and automobiles.

Bradford Miller, a GE cognitive scientist developing more robust AI who spoke at the conference, says the current early generations of collaborative robots now in production, like Baxter, are likely to trigger an evolution in how we think about factories, but they don’t represent the really large breakthrough still on the horizon. “The really big thing is yet to come,” he says. “Transformation will come in the form of learning — when we can get the robots to start learning like children do, and we get their memory to be more episodic like humans, and we get their reasoning up to the point where it can be used to make inferences about things. It will be a disruptive change where human knowledge is transferable to a machine.”

Miller is a proponent of collaborative automation, one of the paths roboticists are taking to make machines think. They all involve improving hardware, artificial intelligence, power usage and machine communications with other machines and people through the Industrial Internet.

But the paths differ in how much cognition is enough to give the machines. Miller wants to see an industrial world populated by robots that he likens to those inhabiting the Star Wars movies — independently operating, thinking machines that learn the world as they experience it and work with their human counterparts in complete partnership.

A necessity in making this idea reality, though, is programming in an “ethical governor” to keep a learning robot in the service of its human creators. We need to “implement robots that understand the consequences of their actions,” Miller says.

Others in the field are taking a different tack, one that seeks to give collaborative robots less of a contemplative bent. Erik Nieves, the founder and CEO of startup PlusOne Robotics, espouses what he calls a human-centric robot strategy that teams less thoughtful machines with human supervisors, allowing for the team to operate more effectively. This approach, he says, doesn’t seek to install fully formed mental states in robots. Instead, bots are primarily a way to augment and extend human abilities.

“As we move forward, yes, robots will need perception to respond to their environment,” Nieves says. “But it is unnecessary to wait until we replicate human cognition in order to further human-robot collaboration. AI robots are decades away. We can begin a much richer collaboration now. We don’t need smarter robots, we need robots connected to smart people. The goal is not to replace or replicate humans and thereby push them out of the equation. We need robots to enhance the effectiveness of humans.”

Nieves uses his own example. He lives in Texas and works in Ohio, but instead of relocating his family or leaving them for extended periods, he works through a telepresence robot. He guides the machine around from the comfort of his home. A screen on the bot with a live video stream beams his face into meetings and onto the factory floor. A camera lets him see what’s going on around the office. “What is needed is my expertise to solve real-time problems, not my physical presence,” he says. “The machine simply facilitates my capabilities remotely. The robot didn’t need to be smart to be useful.”

It’s likely that the future won’t be one path or the other. Rather, it will be a mix where we deploy robots with vastly different capabilities to do the work we need done. Either way, the people building the algorithms and hardware say they are excited about the possibilities they see for how robots can help humanity work smarter and live better.

“The intelligence of robots is increasing, and they’re becoming more connected to each other and to humans,” says Colin Parris, the vice president of software research at GE. “In the next three to four years, software will be writing software, and in five to eight years we’ll have industries that get totally disrupted by robots.”

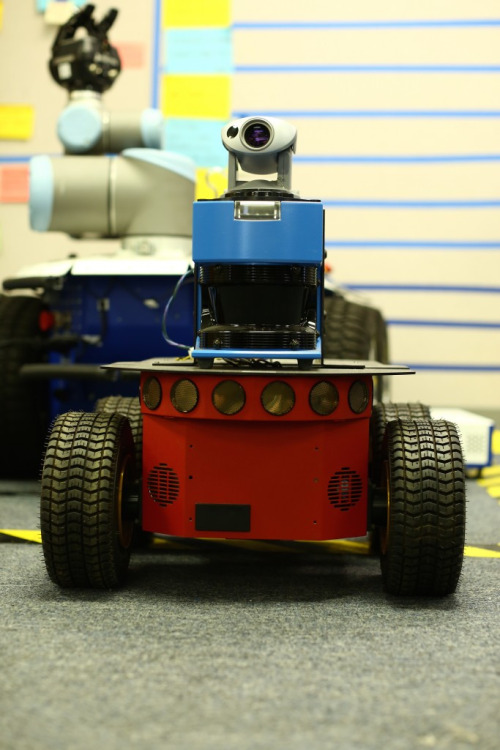

Image credit: GE Global Research