ONCHEK is building Nigeria’s first end-to-end T-shirt manufacturing company, proving that the continent’s next wave of innovation could come not from apps, but from factories powered by data, design, and discipline.

By Eme Bassey

When you buy a T-shirt in Nigeria, chances are it was made thousands of miles away. The cotton may have grown in West Africa, but by the time it returns as a finished garment, it has circled the world, spun, dyed, cut, and stitched in different parts of Asia, then imported back into Lagos.

ONCHEK set out to change that.

Founded in 2016 by Chekwas Okafor, the company started as a curated online marketplace for African fashion brands. By 2019, that vision evolved into something more radical: Nigeria’s first vertically integrated T-shirt manufacturing company, producing 100% locally made cotton garments from yarn to finished product under its homegrown label, Merok.

The new mission is clear: to make the most basic everyday garments in Nigeria — locally, reliably, and profitably.

“We realized the bottleneck wasn’t creativity. It was infrastructure,” says Okafor. “So we stopped trying to sell what others made and started fixing how it’s made.”

The Problem: An Imported Basic

T-shirts are Nigeria’s most common garment: worn for uniforms, campaigns, religious gatherings, campus events, and everyday fashion. Yet, nearly all are imported:

- Nigeria spends over US$4 billion annually on clothing and textile imports, excluding informal trade.1

- Over 250 million T-shirts are imported each year, mostly from China, Bangladesh, and Turkey.2

- In the past five years, Nigeria’s textile import bill rose by nearly 300%, from ₦182 billion in 2020 to ₦726 billion in 2024,3

Buyers face the same frustrations: currency fluctuations, delayed shipments, inconsistent quality, stock-outs, and more.

ONCHEK’s thesis is simple: Eliminate the importation of t-shirts by standardizing quality, stabilizing price, and localizing production.

“The most common garment in Nigeria should not have to travel across three continents,” says CCO Eme Bassey. “We can make it here, at a price point the market accepts, and with quality the market trusts.”

How ONCHEK Builds Locally

Manufacturing in Nigeria isn’t for the faint-hearted. The local textile sector, once the pride of West Africa, has been hollowed out by decades of policy neglect, inconsistent power, and cheap imports.

ONCHEK’s decision to manufacture locally meant navigating every friction point. Rather than wait for perfect conditions, the team built around what exists: regional cotton supply, dormant mills, and a growing urban workforce.

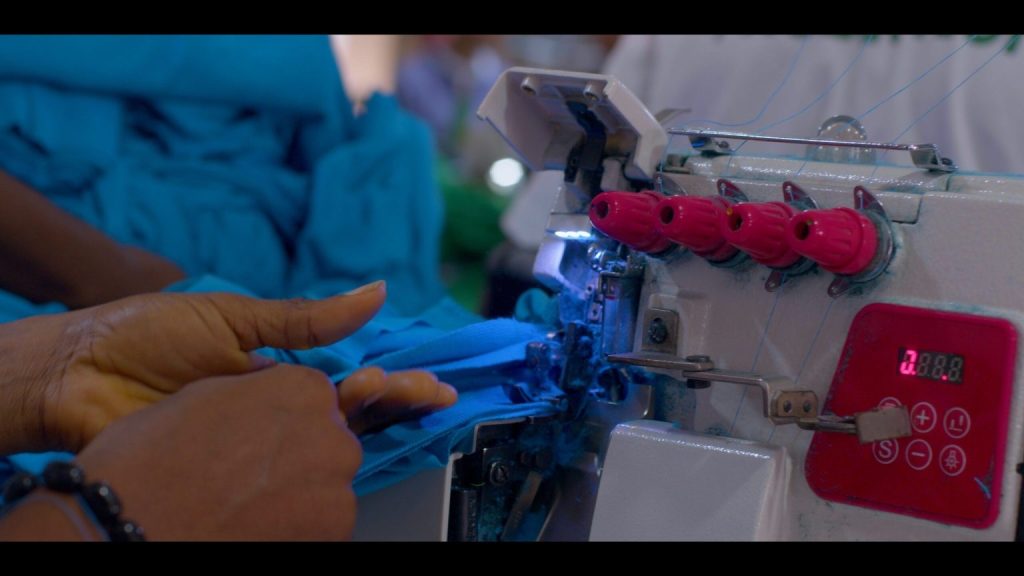

The company’s Mushin textile facility and Satellite Town garment line together form a small but complete ecosystem that demonstrates what can happen when production is intentionally kept local.

Today, ONCHEK operates a micro-industrial ecosystem within Lagos:

- Yarn is sourced from regional mills.

- Fabric is knitted and dyed in Mushin.

- Garments are cut, sewn, and packed in Satellite Town.

Each production run keeps value and skills within Nigeria’s borders.

“The local industry can only recover through use,” says Bassey. “You can’t revive textile mills in theory. You revive them by placing steady orders, building competence, and proving that Nigerian production can meet Nigerian demand.”

ONCHEK’s monthly t-shirt capacity is 200,000 T-shirts per month and is scaling to 500,000 units monthly by mid-2026.

Its average lead time is 7-10 days, compared to 45–90 days for imported alternatives. At scale, ONCHEK’s localized model cuts import-related costs by up to 25% and saves buyers ₦400–₦700 per shirt by eliminating freight, customs, and forex volatility.

Why It Matters: The Next Frontier of African Innovation

In Africa’s tech narrative, startups often solve digital problems. ONCHEK is solving a physical one first.

By combining digital systems, process innovation, and manufacturing, ONCHEK points to the next wave of African startups: those building the physical foundations of the digital economy.

As ONCHEK grows, it will do more than sell T-shirts. It will prove that mass-market apparel can be made in Nigeria at quality and scale, and that local manufacturing can once again compete globally.

“We’re focused on one thing,” Okafor says. “Making quality basics, consistently, in Nigeria.”

The Bigger Picture: From Factory to Platform

ONCHEK’s long-term vision is to expand its manufacturing model into a connected production platform that links demand with verified local capacity.

For SMEs, it means faster access to quality T-shirts for merch, uniforms, or branding.

For corporates, it’s bulk procurement that meets international standards, without import delays.

For policymakers and investors, it’s a model for rebuilding industrial ecosystems through modern execution.

ONCHEK’s journey is still in early stages. But it offers a glimpse of how data and systems can modernize an old industry, build resilience, and create jobs at scale.

👋🏾Meet ONCHEK at Moonshot

ONCHEK will be at TechCabal’s 2025 Moonshot Conference, joining other founders building Africa’s next wave of innovation.

If you spot someone wearing a T-shirt that reads “the t-shirt guy,” that’s us. Please say hi! We’d love to connect, talk local manufacturing, and maybe even supply your next batch of T-shirts.