When you think of oilfield operations, you imagine heavy machinery, miles of rugged terrain, and the relentless drive to keep production steady. What’s often unseen, however, is the complex challenge of keeping those sites powered, connected, and secure in some of the harshest and most remote environments in the country.

For years, field teams across Nigeria’s oil and gas installations relied on manual oversight — daily visits to check solar batteries, restart faulty systems, and maintain surveillance feeds meant to deter theft or monitor production. It was a cycle of repetition, high operational costs, and significant downtime whenever equipment or networks failed.

The challenge beneath the surface

The legacy setups were functional but fragile. Each site typically depended on a small solar panel, a battery pack, and a MiFi router to keep surveillance cameras and sensors online via local mobile networks. But the system buckled under real-world conditions. Solar efficiency dropped during cloudy days, coverage was inconsistent, and theft of field components became a recurring issue. Each failure meant a costly on-site intervention sometimes several hours away from the nearest base station.

A rethink, not a repair

When Fieldbase stepped in, the goal wasn’t just to patch the existing system. It was to re-engineer it for autonomy, resilience, and intelligence.

The first focus was power. Fieldbase developed a custom power module capable of sustaining operations for up to three days in full sunlight and an impressive two days even under cloudy conditions. The design integrated intelligent remote monitoring, enabling real-time visibility into battery health, inverter performance, and solar input. What was once guesswork became data-driven.

The connectivity breakthrough

The real turning point came when Fieldbase replaced unreliable local mobile links with Starlink, the low-earth orbit satellite service that’s redefining connectivity across Africa.

With Starlink in place, connectivity became fast, stable, and available everywhere no more boosters, blackouts, or blind spots. Field engineers could monitor video feeds, receive instant alerts, and perform diagnostics remotely without setting foot in the field.

Built for harsh environments

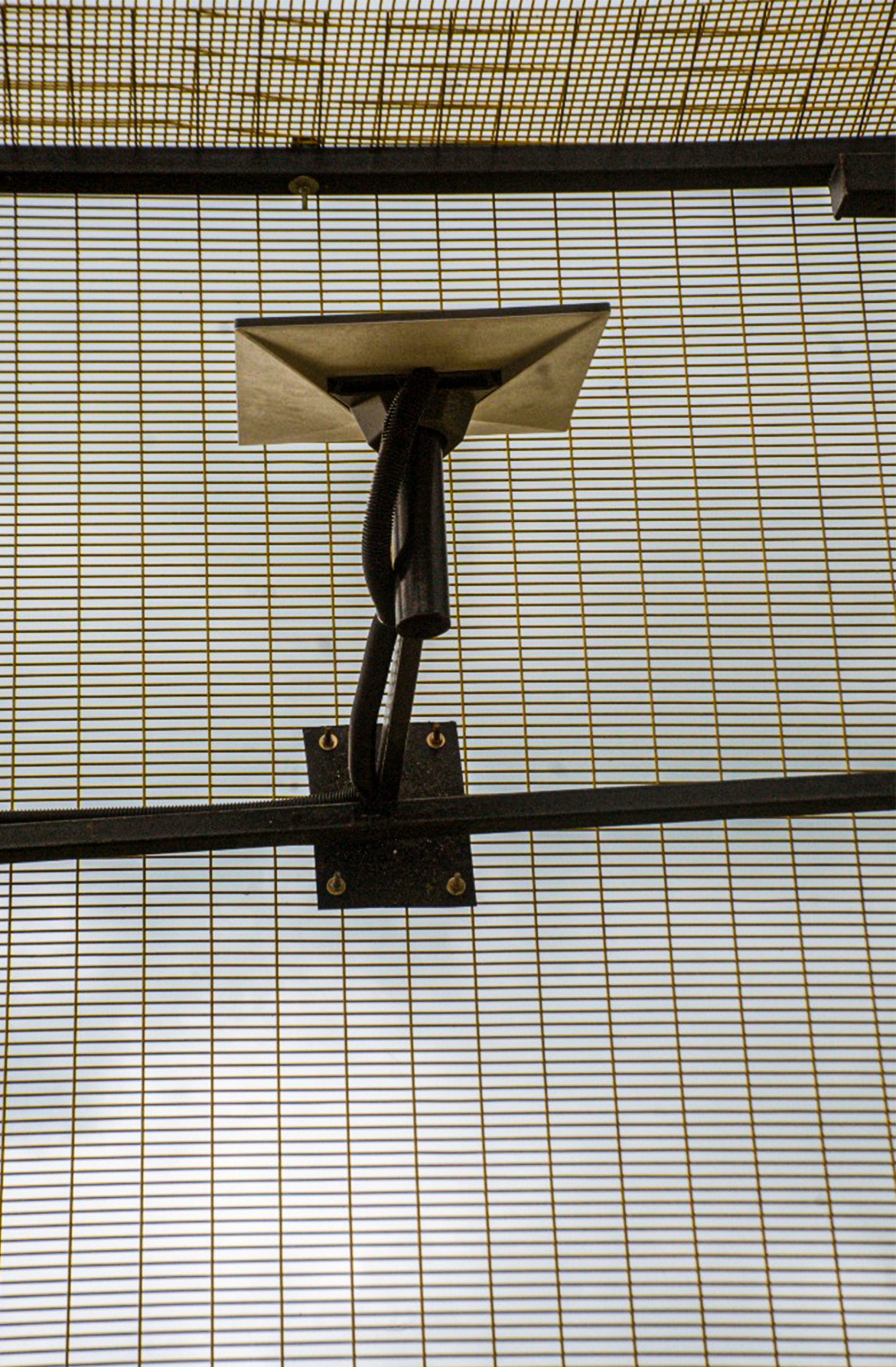

To secure this new system, Fieldbase designed and built a rugged, explosion-proof enclosure housing the inverter, batteries, and Starlink terminal. Beyond durability, the enclosure was engineered for intelligence, capable of remote monitoring, with both DC and AC outputs to power additional field sensors.

Among these sensors was a vibration-detection module that triggers a buzzer and alert when tampering or movement is detected near the equipment. It’s a simple but powerful combination of deterrence, automation, and data.

From daily visits to true autonomy

The transformation was immediate. What previously required daily site visits now runs autonomously for days, with maintenance decisions driven by real-time performance data. The result is fewer field deployments, reduced operational costs, and significantly improved uptime across oilfield infrastructure.

Why it matters

The oilfield solution pioneered by Fieldbase represents a broader shift in how Africa’s industrial operations are evolving. Smart infrastructure, powered by satellite internet and intelligent energy systems, is no longer a future vision, it’s already reshaping the realities of remote work and monitoring.

What Fieldbase has built is more than a connectivity solution; it’s a blueprint for digital transformation in off-grid industries, where automation, satellite connectivity, and renewable energy combine to create self-sustaining, data-powered operations.